Anti-friction

coating

for ICE parts

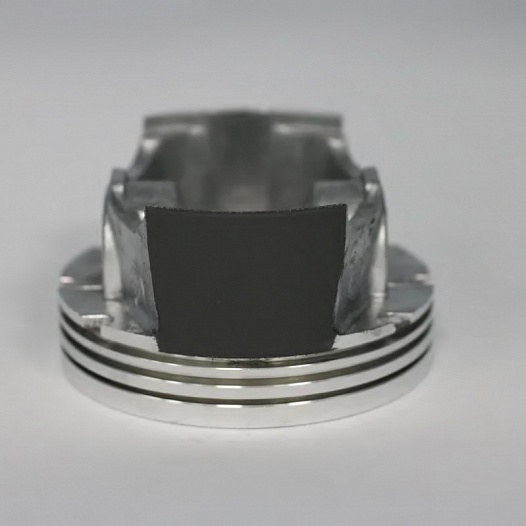

skirts, restore the worn factory coating layer

Applying the coating out of the aerosol can

Use MODENGY Special Cleaner-Activator

to prepare and clean the surface.

Only it guarantees good adhesion

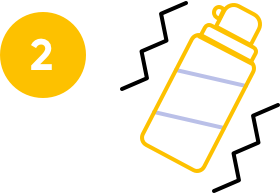

Keep shaking the aerosol can with the coating for at least 3 minutes after you hear tapping of a little ball inside it

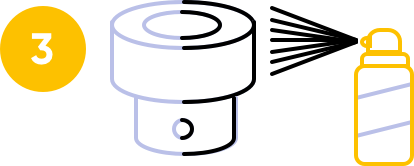

Spray the coating from the aerosol can onto the surface to be treated from the distance of 20 to 30 cm

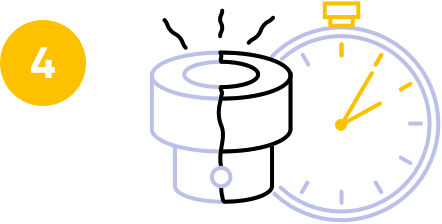

Let the coating dry for at least 10 minutes at room temperature until opacity appears (it’s the interim air-drying stage)

Apply the second layer of the coating over the dried previous one, if necessary

Let the coating dry for at least 12 hours at room temperature (it’s the final air-drying stage)

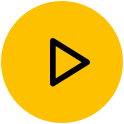

Advantages of MODENGY Anti-Friction Coating for Engine

It protects against scuffing at the engine cold start

It serves as anti-emergency coating under conditions of so called oil starvation, or when engine gets overheated

It reduces friction

It extends the engine service life

It cures at room temperature

Low friction coefficient

Balanced aerosol package with accurately adjusted spraying parameters for even applying

The unique technology is available for anyone

How does the MODENGY coating for engine operate?

MODENGY Anti-Friction Coating for inner combustion engine parts is a modern development of the Modeling and Engineering Russian company.

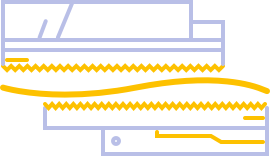

The coating consists of the finest particles of the solid lubricating materials (molybdenum disulfide and graphite) which are spread evenly in the mixture of a binding substance and a solvent.

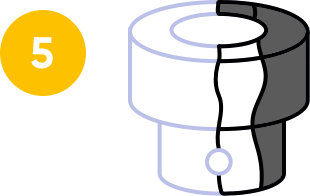

As soon as the coating has been applied, the solvent evaporates. The binding substance cures, and thus, provides reliable adhesion with the piston skirt, and effective fixing of the solid lubricating material particles. A smooth and very slippery 15 to 25 µm thickness dry lubricating film is forming on the surface.

The molybdenum disulfide and graphite particles fill in the surface microroughness cavities. Due to this, its carrying capacity and EP quality improve, and make running-in easier. The coating enables to achieve low and stable friction even at the extremely high contact pressure values.

It increases the engine’s

efficiency coefficient

It reduces friction

It reduces fuel consumption

It prevents scuffing in the

oil starvation mode

It decreases noise

It slows down wear

Use only MODENGY Special Cleaner-Activator to prepare the surface!

The unique formula of the compound developed by our specialists enables to clean and activate a surface before applying the coating in a perfect way.

Only the MODENGY Special Cleaner-Activator can provide the best adhesion of the coating!

The special cleaner-activator enables to remove uncured coating easily (for instance, drips when applied untidily)

Surface preparation is exactly what defines quality of the coating to be gained and its durability. A strong coating can be gained only due to impeccable surface preparation.

Attention! Only application of MODENGY Special Cleaner-Activator before applying the coating guarantees getting the best result!