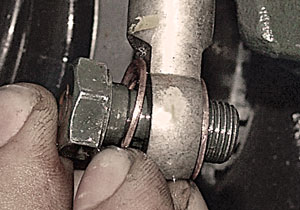

Products for threaded connections

Designed exactly for the threaded connections, Molykote and Dow Corning products have the properties to meet virtually any possible operation conditions.

Typical functions of the products for threaded connections

1

1They provide smooth runnung, movement without jerks

2

2They protect from corrosion formation

3

3They prevent from seizure and jamming

4

4They enable to control tightening torque while mounting

5

5They operate at extremely low and high temperatures

6

6They make mounting and dismantling easier

Product types for threaded connections

1Anti-Friction Coatings

1Anti-Friction Coatings 2Thread Pastes

2Thread Pastes 3Lubricating materials with penetrating properties

3Lubricating materials with penetrating properties 4Protective Coatings

4Protective Coatings

What are these products like?

Anti-friction coatings (AFC) are like paints but contain solid lubricant particles instead of dyeing pigment which are evenly distributed in the mixture of resins and solvents. Unlike conventional lubricants, these products are applied beforehand and are ready to use after cure cycle by forming a kind of coating of the finest solid lubricant particles in a polymer matrix.

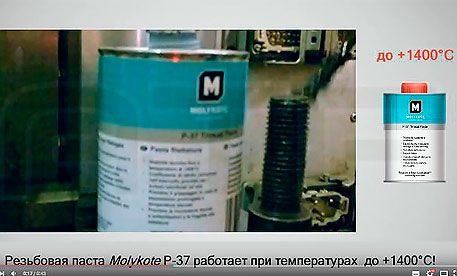

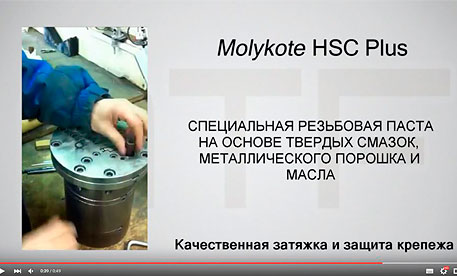

Pastes are solid lubricating materials (graphite, molybdenum disulphide, oxides, hydroxides, metal phosphates, copper powders and special compositions) which are dispersed in oil to make applying process more convenient and to increase adhesion. Optimally selected ratio of the components allows to achieve their synergistic interaction and receive high performances of the whole composition while its cost is the lowest.

Products with high penetrating abilities have lubricating and anti-corrosion properties which are defined by the base oils, the solid lubricants, the inhibitors and the solvents in their composition.

Protective coatings are made on base of synthetic wax with corrosion inhibitors and have melt temperature up to +120°С. They have low friction coefficient, excellent adhesion, increased hardness, high corrosion resistance.

How to select proper product to solve challenges and typical issues while using threaded connections

| Challenge / issue to be solved | Product |

|---|---|

|

A wide range of tightening torque |

Molykote 1000 Thread Paste Molykote P-37 Extremely Pure Thread Paste Molykote D-7405 Anti-Friction Coating

|

| Scuffing formation on the threads and damage of the components during mounting and dismantling caused by high loads |

Molykote G-Rapid Plus Assembly Paste Molykote HSC Plus Electricity-Conductive Thread Paste Molykote P-37 Extremely Pure Thread Paste Molykote D-321 R Anti-Friction Coating Molykote D-3484 Anti-Friction Coating

|

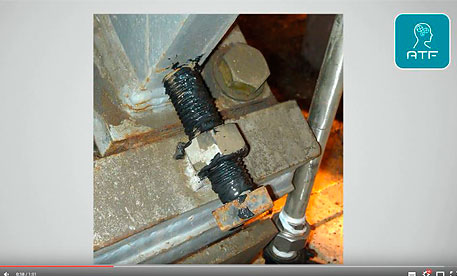

| Corrosion and damage of the threaded connections exposed to the corrosive environments |

Molykote Cu-7439 Plus Lubricating Paste Molykote P-40 Lubricating Paste

|

| Fretting corrosion and scuffing formation on the threads of the components made of the austenitic stainless steels |

Molykote D Paste Light Assembly Paste Molykote P-74 Thread Paste Molykote 1000 Thread Paste Molykote P-37 Extremely Pure Thread Paste Molykote D-321 R Anti-Friction Coating

|

| Fretting corrosion and scuffing formation on the galvanized components threads |

Molykote G-Rapid Plus Assembly Paste Molykote D-321 R Anti-Friction Coating Molykote D-3484 Anti-Friction Coating Molykote D-96-NTP Anti-Friction Coating

|

| Damage of the bolts of heat-resistant alloys caused by cracks formation on the threads | Molykote P-37 Extremely Pure Thread Paste |

| Difficulties with dismantling caused by corrosion and sticking |

Molykote Multigliss Dispersion Molykote Supergliss mineral oil based lubricating product

|

| Corrosion during storage and transportation | Molykote Metal Protector Plus Anticorrosive Coating |

Advantages of the products for threaded connections

They provide minimal friction coefficient

They provide minimal friction coefficient They form dry lubricating film preventing dust sticking onto the surface

They form dry lubricating film preventing dust sticking onto the surface They are heat- and frost-resistant

They are heat- and frost-resistant They are thermally stable

They are thermally stable They are resistant to radiation

They are resistant to radiation They are resistant to chemically active environments

They are resistant to chemically active environments They are able to operate in vacuum

They are able to operate in vacuum They protect from corrosion

They protect from corrosion They provide lubrication for whole service life

They provide lubrication for whole service life They provide stable tightening coefficient

They provide stable tightening coefficient

Typical applications of pastes, anti-friction coatings and other products for threaded connections

Services and training

Learn more about products for threaded connections and our services on their application or order them

Please, fill out the form below. Our manager will contact you for further details of your request very soon.

To keep our dialogue and interaction with our custumers, we arrange training and provide services on applicaion of the specialty materials onto the threaded connections. At the first stage we provide complex expertise of the item. According to its results, we select the proper product type and brand as well as define the surface preparation methods and the ways of its applicaion. The final stage after application includes quality control such as uniformity of the product deposition and degree of AFC polymerization.