ATF is the authorized distributor on promoting the advanced technology products of MODENGY, EFELE, DOW, Molykote brands over the territory of the Russian Federation

If you need to improve your productive processes, to open new markets, or to gain competitive advantage, our team is ready to help you with that, and will do so with an impeccable quality.

Sergey Golubov

Sergey GolubovGeneral director

Products

& Solutions

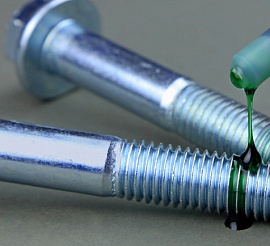

- Anaerobics

- Anti-Friction Coatings

- Protective coating

- Lubricating Oils

- Materials in dispensers

- Food grade materials

- Equipment

- Cleaners

- Pastes

- Greases

- Materials for metalworking

- Primers

- Two-component sealants

- One-component sealants

- Activators and Cleaners

- Anaerobics

- Medical Device Grades

- UV-light Cure Adhesives

- Structural Acrylic Adhesives

- Epoxies

Industry solutions for business

Administrative Office: 2, Marksistskaya Street, bldg. 1, Moscow, 109147, Russia

Engineering Center: office 1, 34B, Olega Koshevogo street, Bryansk, 241029, Russia

Storage Сenter: Moscow Center of Lubricating Materials, Land "Agrokompleks", microdist. Vostryakovo, Domodedovo, Moscow region,142000

+7 (495) 974-97-73