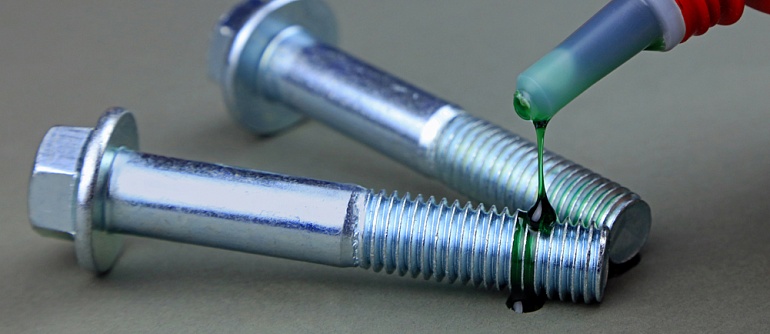

Thread adhesive: features and material choice criteria

Thread adhesive is an important component in the fastening materials world which is specific substance intended to provide reliability and durability of threaded connections.

Food grade gear oil. Reliability and safety at production

In this article, we’ll consider key aspects of a food grade gear oil, its advantages, and importance of using it in industrial processes.

All-purpose lubricoolants: efficient solution for industry

All-purpose lubricoolants are multifunctional products providing integrated solution to lubricate, cool down, and protect the equipment